Digital pressure gauges

6500 INR/Number

Product Details:

- Glass Size Polycarbonate / Tempered Glass

- Bourdon Tube Stainless Steel / Copper Alloy (if applicable)

- Case Stainless Steel / Aluminum / Plastic

- Display LCD / LED, Backlit

- Thread 1/4 or 1/2 NPT, BSP, G

- Sensor Type Piezoelectric / Strain Gauge

- Outer Size 63 mm / 100 mm / 150 mm (standard options)

- Click to view more

X

Digital pressure gauges Price And Quantity

- 3000.00 - 6500.00 INR/Number

- 6500 INR/Number

- 100 Number

Digital pressure gauges Product Specifications

- Stainless Steel / Aluminum / Plastic

- Stainless Steel / Copper Alloy (if applicable)

- Industrial / High Accuracy

- 63mm Millimeter (mm)

- Polycarbonate / Tempered Glass

- 1/4 or 1/2 NPT, BSP, G

- 150 mm Nanometer (nm)

- Max 400 bar

- 63 mm / 100 mm / 150 mm (standard options)

- Industrial, hydraulic, pneumatic, and laboratory pressure measurement.

- 150mm Millimeter (mm)

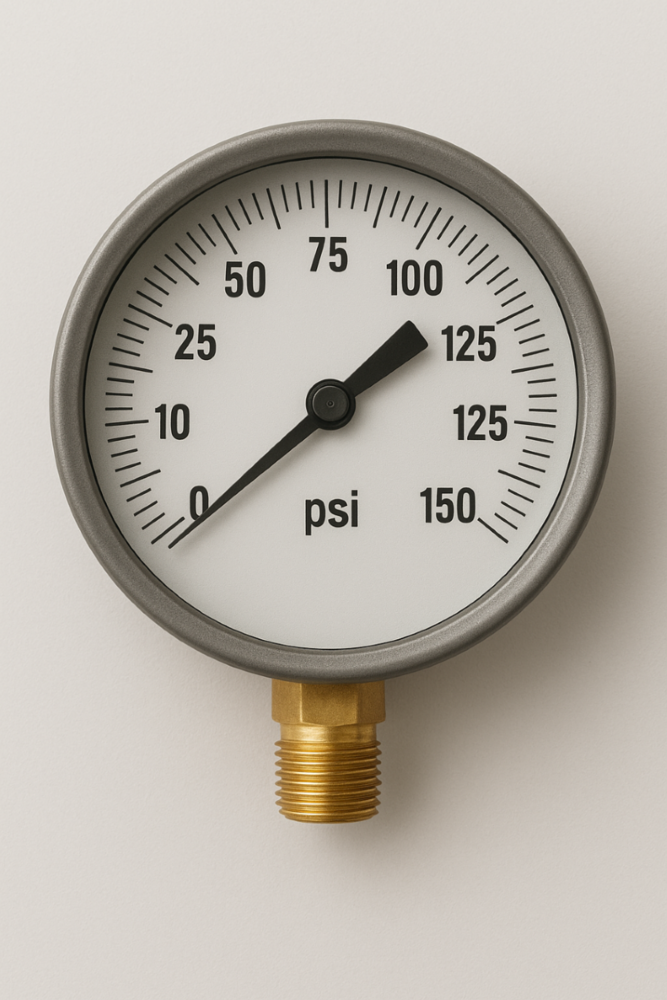

- Silver/Black housing with black digits on white/grey LCD (backlit blue/white).

- Piezoelectric / Strain Gauge

- NBR / Viton / Silicone

- 0.25% FS / 0.5% FS %

- Standard 63mm, 100mm, or 150mm diameter (varies by model).

- Pressure Gauges

- Stainless Steel / Aluminum

- LCD / LED, Backlit

- 150500g (depending on model and size). Grams (g)

Digital pressure gauges Trade Information

- 5000 Number Per Month

- 5 Days

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

-

The Digital Pressure Gauge is a highprecision instrument designed for accurate measurement of pressure in industrial hydraulic and pneumatic systems Featuring a clear LCDLED display with selectable units bar psi kPa MPa it ensures fast and reliable readings Constructed with robust stainless steel or aluminum housing it offers IP65IP67 protection against dust and water making it suitable for harsh environments With options for battery or USB power and versatile pressure connections NPT BSP G it combines durability with convenience Ideal for process monitoring laboratory use and general industrial applications

Key Features

High accuracy 025 FS 05 FS

Pressure range 01 to 0400 bar Vacuum Pressure

MaxMin memory Peak hold Tare function Autooff

Compact design with backlit LCDLED display

Suitable for industrial hydraulic and pneumatic system

Unmatched Precision for Diverse Applications

Our digital pressure gauges excel in delivering reliable pressure measurements, vital for industrial, hydraulic, and pneumatic systems, as well as laboratory research. With high accuracies of 0.25% FS and 0.5% FS, these gauges ensure flawless control and monitoring, enhancing operational safety and quality wherever precise pressure data is essential.

Flexible Design and Durable Construction

Choose from models with stainless steel, aluminum, or plastic cases, and robust Bourdon tubes made from stainless steel or copper alloy. The gauges are available in multiple sizes (63mm, 100mm, 150mm), and feature versatile thread options (1/4 or 1/2 NPT, BSP, G) for simple integration and long-term durability in challenging environments.

Advanced Display and Sensor Technology

Our digital gauges incorporate innovative LCD or LED backlit screens in silver or black housings, with clear black digits on white or grey backgrounds. Accurate readings are ensured using advanced piezoelectric or strain gauge sensors, supported by high-quality seal materials for reliable performance under pressure up to 400 bar.

FAQs of Digital pressure gauges:

Q: How do I choose the right digital pressure gauge model for my application?

A: Select a model based on your specific usage (industrial, hydraulic, pneumatic, or laboratory), required accuracy (0.25% FS or 0.5% FS), pressure range (up to 400 bar), and installation requirements such as thread type (NPT, BSP, G). Also, consider housing materials and gauge diameter (63mm, 100mm, or 150mm) depending on environmental and space constraints.Q: What benefits do digital pressure gauges offer over analog types?

A: Digital pressure gauges deliver higher accuracy, clear visual readings via LCD or LED displays, and enhanced reliability. They are less susceptible to parallax errors and often provide additional features like backlighting for improved visibility in low light and advanced sensor technologies for stable, repeatable measurements.Q: Where can digital pressure gauges be used most effectively?

A: These gauges are suitable for diverse applications, including industrial automation, hydraulic systems, pneumatic circuits, and laboratory testing. Their robust construction and high accuracy make them ideal for settings demanding precise and dependable pressure readings.Q: What is the process for installing a digital pressure gauge?

A: Installation begins by selecting the appropriate thread type (1/4 or 1/2 NPT, BSP, or G) and ensuring compatibility with the system. Securely attach the gauge to the pressure port using the recommended seal material (NBR, Viton, or Silicone), power on the device, and calibrate as specified in the manufacturers manual.Q: When should I consider recalibrating my digital pressure gauge?

A: Regular calibration is advised annually or as recommended by the manufacturer to maintain measurement accuracy. More frequent calibration may be necessary in critical or high-usage environments to ensure ongoing reliability.Q: What sensor types do these pressure gauges use, and what are their advantages?

A: Depending on the model, the gauges utilize piezoelectric or strain gauge sensors. Piezoelectric sensors offer quick response and durability, making them suitable for dynamic pressures, while strain gauge sensors provide excellent stability and high accuracy for static and dynamic pressure measurements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese