Homogenizer /Triclover Pressure Gauge

1800 INR/Piece

Product Details:

- Bourdon Tube Diaphragm / Capsule type for sanitary application

- Glass Size Tempered Safety Glass, 100 mm / 150 mm

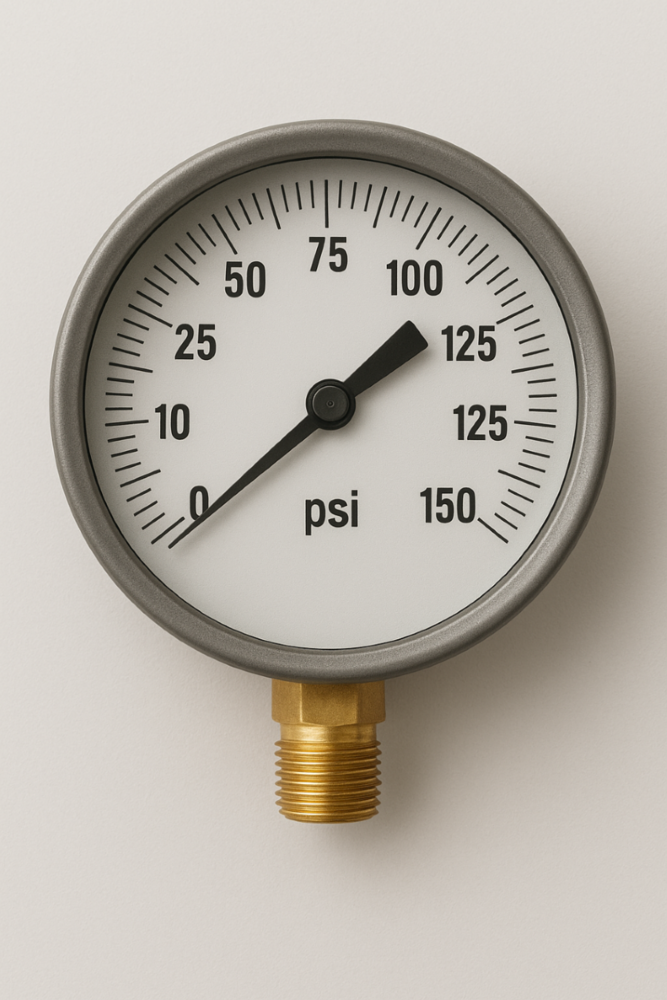

- Display Analog Dial with Black Markings on White Background

- Outer Size Standard (depends on dial chosen)

- Frequency N/A (Analog Mechanical Gauge) Hertz (HZ)

- Thread Triclover Clamp Connection (1.5 / 2)

- Case Stainless Steel, Glycerin Filled (optional for vibration resistance)

- Click to view more

X

Homogenizer /Triclover Pressure Gauge Price And Quantity

- 10 Number

- 1800 INR/Piece

Homogenizer /Triclover Pressure Gauge Product Specifications

- EPDM / PTFE / Silicone (food-grade options)

- Triclover Clamp Connection (1.5 / 2)

- Silver (Stainless Steel Finish)

- 100 mm / 150 mm

- 1.6% of Full Scale %

- Mechanical (Diaphragm Based)

- Triclover Sanitary Pressure Gauge

- Standard 100150 mm (depending on dial) Millimeter (mm)

- Upto 10 bar (custom ranges available)

- Approx. 0.8 1.2 kg (depending on dial size) Kilograms (kg)

- Stainless Steel, Glycerin Filled (optional for vibration resistance)

- Standard (depends on dial chosen)

- Diaphragm / Capsule type for sanitary application

- Food And Beverages Industry, Pharmaceutical Manufacture, Chemical Processing, Water Engineering

- SS304 / SS316 Food Grade Stainless Steel

- Analog Dial with Black Markings on White Background

- Tempered Safety Glass, 100 mm / 150 mm

- Customizable as per fitting Millimeter (mm)

- Standard 3040 mm (approx.) Millimeter (mm)

- Stainless Steel SS304 / SS316

- Pressure measurement in sanitary & hygienic applications

- N/A (Analog Mechanical Gauge) Hertz (HZ)

Homogenizer /Triclover Pressure Gauge Trade Information

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 100 Number Per Week

- 5 Days

- Yes

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

The Homogenizer Triclover Sanitary Pressure Gauge is a specially designed instrument for hygienic and sanitary applications in the food dairy beverage pharmaceutical and biotechnology industries Equipped with a triclover clamp connection it ensures easy installation cleaning and maintenance while maintaining strict sanitary standards

Manufactured from SS304SS316 stainless steel the gauge is highly resistant to corrosion and suitable for use with liquids semisolids and sensitive process media It features a clear analog dial 100 mm 150 mm with precise markings providing accurate and reliable pressure readings up to 010 bar Optional glycerin filling minimizes vibration effects and ensures longer service life

This pressure gauge is widely used in homogenizers pipelines fermenters and sanitary process equipment ensuring safe and efficient monitoring of pressure in critical applications

Engineered for Hygiene and Safety

Manufactured with food-grade materials and designed for sanitary fittings, this gauge meets stringent industry standards for hygiene. Its stainless steel construction resists corrosion, ensuring safety for direct contact applications in food, beverage, and pharmaceutical processing.

Precision and Versatility for Multiple Industries

Supporting operational flexibility, the gauge is suitable for diverse fields such as chemical processing and water engineering. The diaphragm or capsule-type Bourdon tube delivers consistent accuracy across various applications requiring precise pressure monitoring.

Customizable Installation Options

Available in multiple dial sizes, lengths, and pressure ranges, the gauge fits seamlessly into custom setups. The optional glycerin filling enhances durability in high-vibration environments, while the analog dial ensures straightforward, at-a-glance readings.

FAQs of Homogenizer /Triclover Pressure Gauge:

Q: How does the Triclover Pressure Gauge ensure hygienic measurement in food and beverage applications?

A: The Triclover Pressure Gauge uses food-grade SS304/SS316 stainless steel and sanitary clamps, plus EPDM, PTFE, or silicone seals, ensuring all wetted parts are safe for hygienic environments required by food and beverage industries.Q: What is the process to install this gauge in a sanitary pipeline system?

A: Installation involves connecting the Triclover clamp fitting (1.5 or 2) to the corresponding sanitary ferrule on the pipeline, ensuring proper gasket placement and secure tightening to prevent leaks during operation.Q: When should I choose the glycerin-filled option for my application?

A: Glycerin filling is recommended for environments with significant vibration or pulsation. It dampens shock, stabilizes the needle, and prolongs gauge life by reducing internal wear from mechanical vibrations.Q: Where is this pressure gauge typically used?

A: Common applications include sanitary processes in the food and beverage industry, pharmaceutical manufacturing, chemical processing, and water engineering, where maintaining hygiene and accurate pressure measurement is essential.Q: What benefits does the mechanical (diaphragm based) sensor provide compared to other sensor types?

A: A mechanical diaphragm sensor offers reliable, maintenance-free operation without the need for external power. It is ideal for sanitary environments due to its robust and contamination-resistant design.Q: How accurate is the gauge and why does this matter for critical processes?

A: The gauge provides an accuracy of 1.6% of the full scale. High accuracy is vital for quality control and safety in sensitive processes where precise pressure monitoring is crucial to product consistency and regulatory compliance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese